Welcome to Our Company

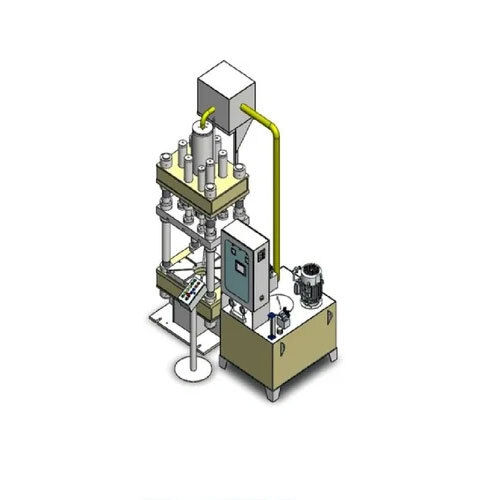

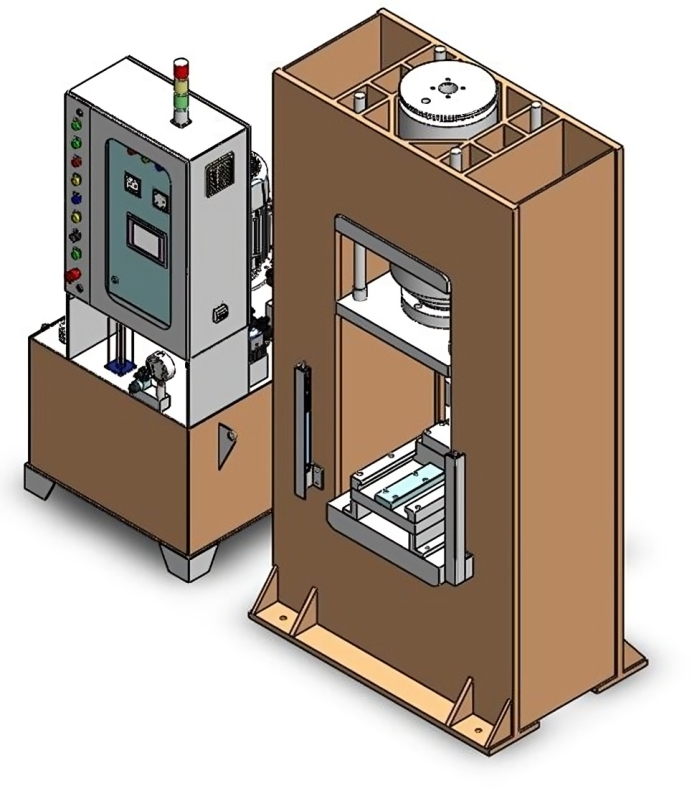

JSD Make Hydraulic Up Stroking Press

550000 INR/Number

Product Details:

- Shape Rectangular Base with Moving Upper Platen

- Diameter Cylinder diameter customizable as per tonnage

- Phase Three Phase

- Torque Hydraulic Cylinder based, not torque-rated

- Product Type Hydraulic Up Stroking Press

- General Use Industrial Metal Forming and Pressing Applications

- Material High Grade Mild Steel IS Standard

- Click to View more

X

JSD Make Hydraulic Up Stroking Press Price And Quantity

- 1 Number

- 550000 INR/Number

JSD Make Hydraulic Up Stroking Press Product Specifications

- 0.2 mm

- Hydraulic Cylinder based, not torque-rated

- High Grade Mild Steel IS Standard

- PLC Based or Electrical Selector Switch Panel

- ISO 9001:2015 Certified

- Robust Construction, High Efficiency, Minimum Maintenance, Reliable Operation

- Varies with capacity (Approx. 1000 7000 kg)

- Optional

- Up Stroking Hydraulic Press

- Three Phase

- Cylinder diameter customizable as per tonnage

- No

- Provided upon request

- Customized as per Model (Example: 2400 x 1200 x 2200 mm)

- Rectangular Base with Moving Upper Platen

- Hydraulic Up Stroking Press

- Powder Coated & Painted

- Industrial Metal Forming and Pressing Applications

- Industrial Blue-Grey (Custom colors available)

- 380V / 415V, 3 Phase, 50 Hz

- Semi-Automatic / Automatic models available

- Ranging from 5 Tons to 300 Tons (customizable)

Product Description

Spotlight your industrial productivity with the latest JSD Make Hydraulic Up Stroking Pressa breathtaking kingly solution engineered for the most demanding metal forming applications. This top-notch, best-seller press features a standard table size of 1200 x 1000 mm, stroke length of 400800 mm, and versatile pressure up to 320 Bar. Its low-maintenance, robust construction ensures years of reliable operation. With customizable capacities (5300 Tons) and state-of-the-art safety, efficiency, and control features, it stands as the industrys preferred choice for performance and dependability.

Exceptional Features & Competitive Advantages

JSD Make Hydraulic Up Stroking Press redefines excellence with robust IS Standard mild steel construction, automatic lubrication, PLC-based stepless pressure adjustment, and extensive safety elements including emergency stop and guards. Its competitive edge lies in low maintenance, efficient energy use, and flexible heating and accessory options like die cushions and ejectors. Ideal for both semi-automatic and automatic metal forming, punching, moulding, and bonding in industries demanding precision and reliability, it adapts to a wide spectrum of application media and workload scales.

Packaging, Shipping, and Quotation Information

Each JSD Make Hydraulic Up Stroking Press is carefully packaged for maximum security, utilizing industrial-grade materials and methods to shield components during transit. We offer secure shipping from major Indian FOB ports and work with trusted transport services to ensure safe, on-time delivery. For quotations, simply contact our sales representatives for comprehensive pricing and customization options. Sample policy and other specific requirements can be discussed at the time of quotation for smooth order processing.

Exceptional Features & Competitive Advantages

JSD Make Hydraulic Up Stroking Press redefines excellence with robust IS Standard mild steel construction, automatic lubrication, PLC-based stepless pressure adjustment, and extensive safety elements including emergency stop and guards. Its competitive edge lies in low maintenance, efficient energy use, and flexible heating and accessory options like die cushions and ejectors. Ideal for both semi-automatic and automatic metal forming, punching, moulding, and bonding in industries demanding precision and reliability, it adapts to a wide spectrum of application media and workload scales.

Packaging, Shipping, and Quotation Information

Each JSD Make Hydraulic Up Stroking Press is carefully packaged for maximum security, utilizing industrial-grade materials and methods to shield components during transit. We offer secure shipping from major Indian FOB ports and work with trusted transport services to ensure safe, on-time delivery. For quotations, simply contact our sales representatives for comprehensive pricing and customization options. Sample policy and other specific requirements can be discussed at the time of quotation for smooth order processing.

FAQs of JSD Make Hydraulic Up Stroking Press:

Q: How does the JSD Make Hydraulic Up Stroking Press ensure operator safety during industrial use?

A: The press is equipped with a suite of safety features, including an emergency stop button, two-hand operation system, and safety guards, helping to ensure maximum operator protection during all phases of operation.Q: What customization options are available for table size, stroke, and tonnage capacity?

A: Customers can request customized table sizes, stroke lengths, and tonnage capacity (ranging from 5 to 300 tons) to suit specific industrial application requirements and workflow demands.Q: When should the optional heating system be used with this press?

A: The heating system is particularly beneficial during moulding or bonding applications, where controlled heat facilitates proper material processing. It can be integrated based on your application needs.Q: Where is this hydraulic press typically utilized within industry sectors?

A: The press is extensively used in metal forming, pressing, punching, moulding, bonding, and fabrication industries across automotive, engineering, appliance, and metalworking sectors.Q: What competitive advantages does the JSD Make Hydraulic Up Stroking Press offer?

A: This model delivers high efficiency with low maintenance requirements, customizable controls (PLC or electrical panel), automatic centralized lubrication, precise 0.2 mm tolerance, and robust, ISO 9001:2015-certified build quality, ensuring dependable, long-term benefits.Q: How can I request a quotation or discuss sample policy for this machine?

A: Reach out to our sales team through official contact channels to receive a detailed quotation. Information on samples and specific requirements can be tailored upon request during the quotation process.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email