Welcome to Our Company

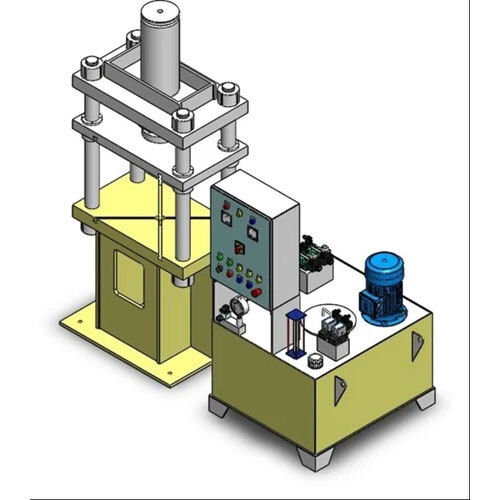

BLOCK TYPE HYDRAULIC CLAMPING CYLINDER

7500 INR/Number

Product Details:

- Wall Thickness Robust block body, typically 12-20 mm

- Capacity 1.5 to 6.5 Tons

- Temperature -20C to +80C

- Pressure Max. 250 bar

- Material High grade steel / Alloy steel

- Structure Block type, double acting

- Power Hydraulic

- Click to View more

X

BLOCK TYPE HYDRAULIC CLAMPING CYLINDER Price And Quantity

- 1 Number

- 7500 INR/Number

- Low leakage rate, high reliability

- ISO 6020/2 and DIN 24336

- Hard chrome plated

- Hydraulic oil ISO VG 46

- Spring return

- Black oxide coating

- Threaded holes and flange mount

- Fixture clamping, precision automation

- Over 5 million cycles

- G1/4" BSP

BLOCK TYPE HYDRAULIC CLAMPING CYLINDER Product Specifications

- High grade steel / Alloy steel

- Hard chrome plated steel

- 25 mm

- Nitrile rubber (NBR) or polyurethane

- Hydraulic

- Robust block body, typically 12-20 mm

- Max. 250 bar

- Varies by model: Typical LxWxH - 120 x 55 x 60 mm

- 3.7 - 11 kg (depending on model)

- Block type, double acting

- -20C to +80C

- 1.5 to 6.5 Tons

- 10 - 50 mm

- Low leakage rate, high reliability

- ISO 6020/2 and DIN 24336

- Hard chrome plated

- Hydraulic oil ISO VG 46

- Spring return

- Black oxide coating

- Threaded holes and flange mount

- Fixture clamping, precision automation

- Over 5 million cycles

- G1/4" BSP

Product Description

The BLOCK TYPE HYDRAULIC CLAMPING CYLINDER is highly recommended for professionals seeking grandiose performance and champion reliability in fixture clamping and precision automation. With a brilliant low leakage rate and over 5 million cycles of service life, this double-acting block type cylinder sets a new standard. Featuring threaded or flange mounts, hard-chrome plated components, and robust, black oxide-coated block bodies, it supports up to 6.5 tons at 250 bar. Order todayavailability is ending soon. Built to ISO and DIN standards, this product is a must-have for any serious manufacturer, distributor, or exporter in India.

Versatility and Industrial Applications

The BLOCK TYPE HYDRAULIC CLAMPING CYLINDER is used for secure fixture clamping in various automated precision setups. Its robust construction is ideal for use in plants requiring reliable, repeated clamping actioncommon in automotive manufacturing, machining centers, and tooling lines. Its grandiose build caters to areas demanding high reliability and long life, making it an excellent solution wherever quick and precise hydraulic clamping is needed for plant operations.

Sampling, Certifications, and Export Markets

Sample pieces of this hydraulic clamping cylinder are readily available for dispatching to ensure selection confidence. Certified to ISO 6020/2 and DIN 24336, this cylinder boasts high market value in global markets including Asia, Middle East, and Europe. As a leading exporter and manufacturer, we maintain a consistent rate of supply, serving industries that demand reliability and durability worldwide.

Versatility and Industrial Applications

The BLOCK TYPE HYDRAULIC CLAMPING CYLINDER is used for secure fixture clamping in various automated precision setups. Its robust construction is ideal for use in plants requiring reliable, repeated clamping actioncommon in automotive manufacturing, machining centers, and tooling lines. Its grandiose build caters to areas demanding high reliability and long life, making it an excellent solution wherever quick and precise hydraulic clamping is needed for plant operations.

Sampling, Certifications, and Export Markets

Sample pieces of this hydraulic clamping cylinder are readily available for dispatching to ensure selection confidence. Certified to ISO 6020/2 and DIN 24336, this cylinder boasts high market value in global markets including Asia, Middle East, and Europe. As a leading exporter and manufacturer, we maintain a consistent rate of supply, serving industries that demand reliability and durability worldwide.

FAQs of BLOCK TYPE HYDRAULIC CLAMPING CYLINDER:

Q: How is the BLOCK TYPE HYDRAULIC CLAMPING CYLINDER mounted?

A: It can be mounted using threaded holes or a flange mount, providing flexibility for various fixture designs and setups.Q: What applications is this hydraulic cylinder best suited for?

A: This cylinder is ideal for high-precision clamping in automation, manufacturing plants, machining lines, and tooling fixtures where reliability and long service life are crucial.Q: When should I replace the seals in the cylinder?

A: Although designed for a service life exceeding 5 million cycles, its best to monitor for leakage or reduced performance and follow the manufacturers guidelines for seal inspection and replacement.Q: Where can this cylinder be shipped from?

A: As a leading distributor and exporter based in India, we dispatch globally, covering Asia, the Middle East, Europe, and other markets.Q: What are the main benefits of choosing this hydraulic cylinder?

A: Key benefits include a brilliant low leakage rate, high pressure and tonnage capacity, extended cycle life, robust construction, and compliance with ISO and DIN standards for quality assurance.Q: How does the return mechanism work in this hydraulic cylinder?

A: It uses a reliable spring return system, enabling the piston to retract automatically after actuation, optimizing operational efficiency in automated processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email